Jim Dalen’s Rib JigJim Dalen, a RagWing Parasol builder sent us a copy of an article he wrote for his

local UL club (the Albuquerque Ultralight Association) newsletter.

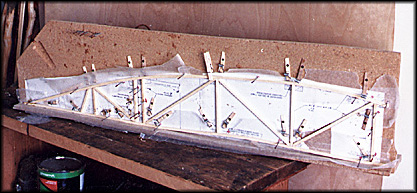

Constructing the wing ribs is still the primary focus in my garage

and I’ve taken some photos of the jig and the assembly process that

might assist another builder. I made the jig from an old section of

preformed countertop. After trimming the excess material, I ended up

with a flat section that is about 16″ X 50″. Nailing and gluing a 1.5″

strip along a factory straight edge at the “wrong side” provided a

perfect 90 degree and straight corner from which to construct the ribs.

A full size rib pattern was then attached to the particle board with

wall paper paste after all key measurements were verified on the

pattern. I started to construct a cam arrangement for alignment during

the rib construction, but found that 8d finishing nails placed into

predrilled 7/64″ holes held the pieces firmly and uniformly in place for

gluing. This jig uses 22 of these “pegs”. The proper placement of the

holes was determined by actual placement and bending of the wood strips.

“See photo # 1). The rib is assembled in the jig by 1st placing the

lower and upper stock in place, fitting and gluing the trailing edge

joint and then fitting, cutting and gluing the remaining stock pieces.

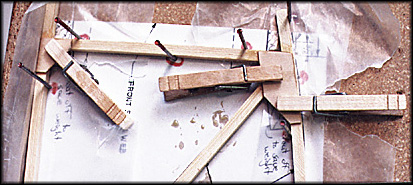

The plans of the Parasol call for the joints in the ribs to just be left

at a 90 degree cut and to rely on the gussets to support the stress at

the joints. I am not comfortable with the resulting gaps so all of the

joints are fit and cut to the proper angel by simply laying the stock

over the existing upper and lower stock at the correct angle as

determined by the plans, marking the correct dimension and angle with a

fine lead mechanical pencil and cutting with a hacksaw. (Photo #2 shows

the fine fit possible by using this technique and also illustrated the

positing of the stock by use of the finishing nail pegs.)

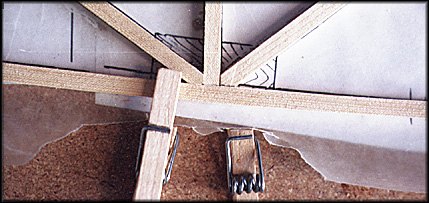

After all the stock is glued, the gussets are cut and glued in place.

I am using the EXCEL glue recommended by Rag Wing and find that it

expands as it dries. The plans for the craft call for use of staples to

secure the gussets until they are dry but I use wood clothes pins to

clamp each gusset in one or two places. Half of the clothes pin was

shorted to just less than the spring slot and then permanently screwed

in place. After the gusset is cut and glue applied, the top half is

simply slipped under the center spring and then acts as a clamp while

the glue dries. (See photo #3 and compare the clamps to photo #2.)

This jig setup works well for me and the only problem encountered was

another case of pilot error when I didn’t get the waxed paper positioned

correctly and glued a peg to the wood stock! That little error proved

the exceptional adhesive qualities of EXCEL glue.

RagWing Aeroplane Company

A RogerMann.org site